The development of a more electric aircraft represents one of the challenges of the technological transition envisaged for a large part of the primary and auxiliary systems of aircraft and helicopters

The aircraft industry has initiated numerous studies and developments for electrical actuation, including the use of electro-hydrostatic actuators (EHA), and has started to introduce electromechanical actuators for auxiliary equipment.

This has necessitated incremental approaches to address hydraulic circuit issues with Power-by-Wire technologies (A320, B777 and Falcon 7X), the introduction of the 2-hydraulic/2-electric (2H/2E) power distribution architecture, in which flight control is powered by EHAs using a local hydraulic reservoir (A380, A350XWB) and EMAs for specific systems (spoilers, brakes and engine starters). Thanks also to various research programmes, EMA systems are now considered the best candidate for replacing current hydraulic and mechanical systems.

This is due to multiple factors :

- Less complexity due to the absence of a hydraulic system;

- More energy efficient than hydraulic systems;

- Easy installation maintenance (no filtration and leaks);

- Less complex power distribution and management (power is transmitted without mass transfer).

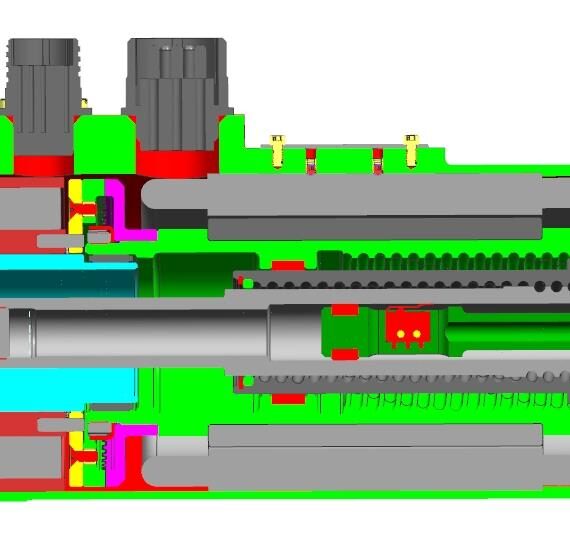

The PHASE-LAG project, started in 2017, aims to develop an electric drive system for the extension-retraction of the main landing gear of the future SMALL A/C.

The main project objectives (FAil-Safe Electro-mechanical actuation for LAnding Gear ) are :

- Development of an electromechanical actuation system (EMAS) for landing gear characterised by reduced size and weight, higher reliability and greater safety margins

- Testing of the EMAS system for the implementation of the landing system in a dedicated test facility (RIG) to verify the achievement of the target TRL

To achieve these goals, the solution will include innovative technologies such as:

- Optimised fail-safe architectures for electromechanical actuatorswith a reduced number of components and the use of new materials, processes and components

- Advanced and reliable electronics considering emerging semiconductors such as SiC and GaN and innovative thermal technologies with intelligent heat management to increase cooling performance and reduce power losses

- Advanced Health Monitoring(Hardware e Software)

- Highly reliable electric machine with an inherent reliable architecture, high performance materials and fault tolerant design

- Advanced control algorithms focused on theoptimising efficiency.